The chemical complex industry is poised for transformative innovations and technologies by 2025, which will redefine how chemical products are manufactured, distributed, and utilized. According to a report by the World Economic Forum, the global chemical industry is expected to reach a market size of $5 trillion by 2025, driven by advancements in sustainability and digitalization. These trends reflect a significant shift towards circular economy practices, where waste is minimized, and resources are continuously repurposed, ultimately creating a more efficient chemical complex.

Dr. Emily Carter, a leading expert in chemical engineering, emphasizes the importance of these advancements by stating, "The future of the chemical complex relies heavily on our ability to integrate innovative technologies that not only enhance production efficiency but also prioritize environmental responsibility." This sentiment highlights the industry's recognition of the critical balance between innovation and sustainability. As we delve into the top trends shaping the chemical complex, we will explore key technologies such as automation, bio-based feedstocks, and advanced material science, accompanied by case studies that illustrate these remarkable shifts in the sector. The journey ahead promises a collaborative effort towards a more resilient and environmentally-conscious chemical complex, paving the way for future generations.

The chemical sector is poised to undergo significant transformations by 2025, driven by several emerging technologies that promise to enhance efficiency and sustainability. One of the most prominent trends is the rise of artificial intelligence and machine learning in chemical production processes. These technologies enable real-time data analysis and predictive maintenance, which can help optimize operations, reduce waste, and lower energy consumption. Moreover, AI applications in research and development can significantly accelerate the discovery of new materials and compounds, potentially leading to breakthroughs in various applications from pharmaceuticals to advanced materials.

In addition to AI, advances in biotechnology are set to reshape the landscape of the chemical industry. The integration of bioprocessing techniques allows for the development of environmentally friendly alternatives to traditional chemical processes. By harnessing microorganisms and enzymes, manufacturers can produce bio-based chemicals that minimize environmental impact and reliance on fossil fuels. Furthermore, the push for circular economy principles is driving innovations in recycling technologies, enabling greater recovery of materials through advanced separation and purification methods. As these technologies evolve, they promise to create a more resilient and sustainable chemical sector, addressing both market demands and environmental challenges.

| Trend | Description | Impact Area | Projected Growth (%) |

|---|---|---|---|

| Green Chemistry | Focus on reducing toxic substances in chemical processes. | Sustainability | 25% |

| Digital Transformation | Integration of IoT and AI for process optimization. | Operational Efficiency | 30% |

| Biotechnological Advances | Use of microbes for sustainable production of chemicals. | Sustainability | 20% |

| Advanced Materials | Development of materials with enhanced properties. | Material Science | 15% |

| Carbon Capture and Utilization | Technologies to capture CO2 and convert it into useful products. | Environmental Impact | 35% |

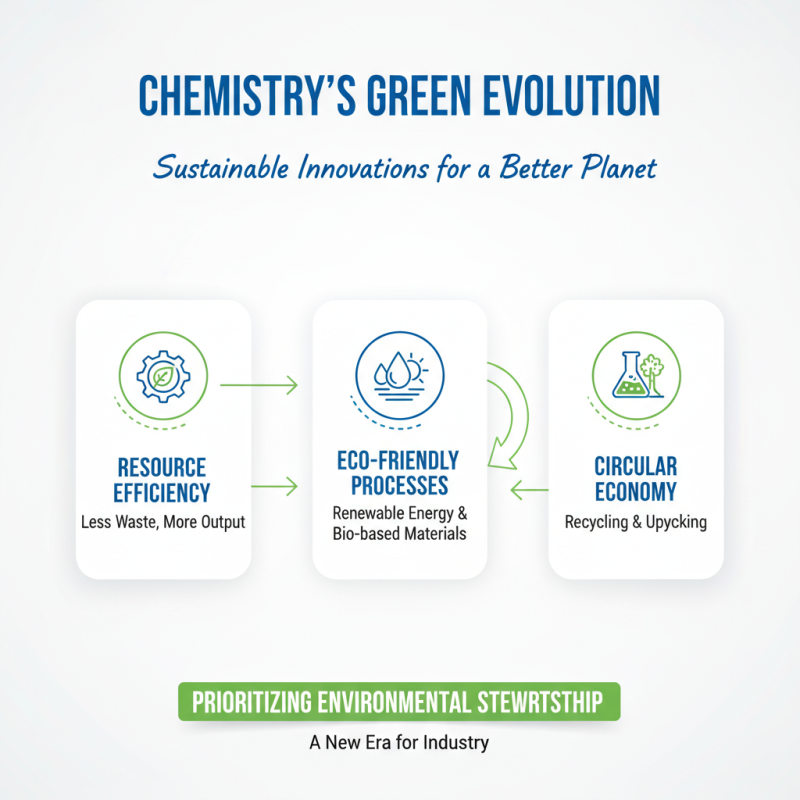

The chemical industry is undergoing a transformative shift toward sustainable practices, with innovations that not only enhance efficiency but also prioritize environmental stewardship. One of the most significant trends involves the adoption of circular economy principles, where waste materials are re-evaluated as valuable resources. By reusing and recycling byproducts from chemical processes, companies can minimize waste and reduce the extraction of virgin raw materials. This approach not only lessens the environmental impact but also drives economic benefits by lowering production costs.

Furthermore, advancements in green chemistry are paving the way for safer, more sustainable chemical processes. Innovations such as biocatalysts and renewable feedstocks are replacing traditional methods that often utilize hazardous substances. This shift not only addresses regulatory pressures but also responds to a growing consumer demand for environmentally-friendly products. The implementation of energy-efficient technologies, such as process intensification and renewable energy sources, is also becoming more prevalent, allowing chemical complexes to operate with a reduced carbon footprint while maintaining productivity and profitability.

The integration of automation and artificial intelligence (AI) in chemical manufacturing is revolutionizing the industry, paving the way for enhanced efficiency and innovation. In 2025, this trend is expected to accelerate, as companies leverage advanced robotics and AI algorithms to optimize production processes. Automated systems can streamline operations by managing supply chains and reducing human error, while AI technologies can analyze vast datasets to predict maintenance needs and optimize energy consumption. This shift not only minimizes downtime but also lowers operational costs, allowing manufacturers to focus on research and development.

Moreover, the application of AI in chemical complex innovations is fostering greater safety and sustainability. Predictive analytics can help identify potential hazards in real time, allowing for swift interventions before accidents occur. Additionally, AI-driven processes contribute to greener manufacturing practices by enabling more precise control over chemical reactions and resource usage. By optimizing formulations and reducing waste, manufacturers are not only improving their bottom line but also aligning with global initiatives to promote sustainable practices in the chemical industry.

The convergence of automation and AI in chemical manufacturing is set to redefine the landscape, making it more efficient and environmentally responsible.

Bioprocessing is poised to revolutionize the chemical industry, particularly in the realm of innovative technologies. As researchers and companies focus on sustainability and efficiency, bioprocessing harnesses biological systems to produce chemicals, materials, and energy. This method not only reduces dependence on fossil fuels but also leverages renewable resources, making it a cornerstone of future chemical technologies. By integrating bioprocessing, companies can develop greener alternatives that meet the increasing demand for environmentally friendly products.

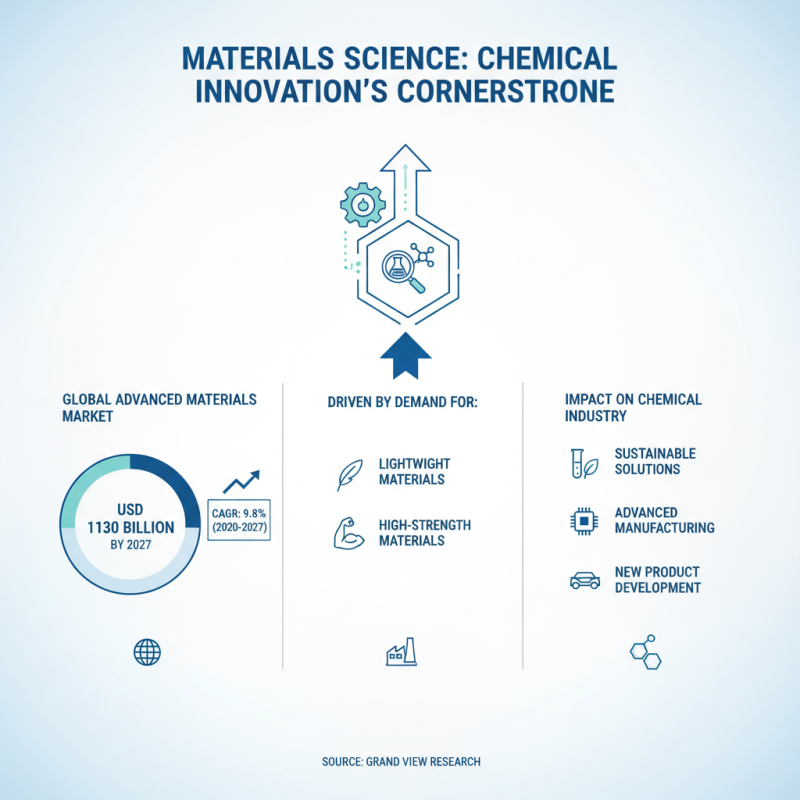

The rapidly evolving field of material science is significantly influencing innovations within the chemical industry. According to a recent report by Grand View Research, the global advanced materials market is expected to reach USD 1130 billion by 2027, expanding at a compound annual growth rate (CAGR) of 9.8%. This growth is primarily attributed to the increasing demand for lightweight and high-strength materials across various applications, making material science a cornerstone of chemical innovations.

Among the emerging trends, biopolymers and nanomaterials are at the forefront. Research indicates that the biopolymer market could grow by 18% annually, driven by their sustainability advantages as alternatives to conventional plastics. Additionally, the development of nanomaterials is revolutionizing sectors from electronics to healthcare, thanks to their enhanced properties, including increased strength and improved chemical reactivity. These advancements not only contribute to better product performance but also align with the industry's shift towards greener, more sustainable practices, ultimately transforming the landscape of chemical manufacturing.

Contact our team with questions, product inquiries or challenge us to engineer a solution for you.

Tel: +1 716 433 6764

Fax: +1 716 433 2850

Email: sale@ashymed.com

VanDeMark Chemical Inc.

One North Transit Road

Lockport, NY 14094 USA