The chemical industry plays a pivotal role in modern society, influencing everything from materials to energy solutions. As we move deeper into 2023, this sector is experiencing a profound transformation, driven by innovative technologies and sustainable practices. The adoption of advanced methodologies not only enhances productivity but also addresses the growing demand for environmentally friendly solutions, making it crucial for the industry to adapt swiftly.

In this landscape of rapid change, understanding the top innovations that are reshaping the chemical industry can provide key insights into future trends and operational strategies. From breakthroughs in green chemistry to the integration of artificial intelligence in production processes, these innovations highlight a commitment to sustainability and efficiency. As industry leaders harness these advancements, the potential for creating a cleaner, more sustainable chemical sector is becoming increasingly attainable.

This exploration of the top 10 innovations transforming the chemical industry in 2023 will delve into how these developments are not just enhancing operational capabilities but are also setting the stage for a more resilient and sustainable future. By examining these trends, we can appreciate the significant impact of innovation on the chemical industry and its crucial role in addressing global challenges.

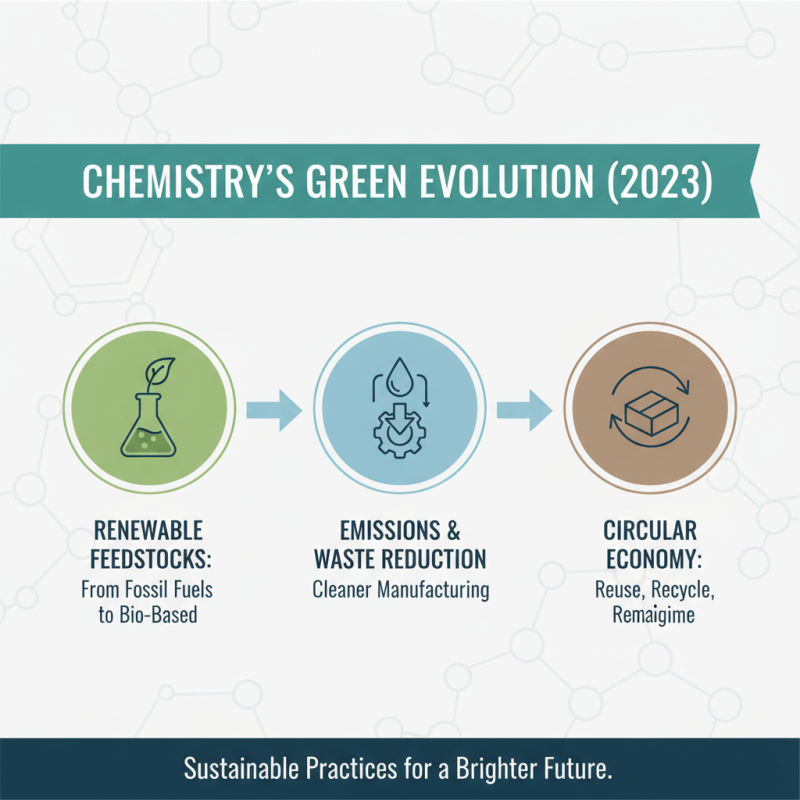

In 2023, the chemical industry is undergoing significant transformation driven by several key trends that are reshaping its landscape. One of the foremost trends is the increasing focus on sustainability and environmental stewardship. Companies are investing in green chemistry practices, which emphasize the reduction of waste and the use of renewable resources. This shift not only addresses regulatory pressures but also aligns with consumer demand for more sustainable products. Innovations such as bio-based chemicals and energy-efficient processes are becoming standard, helping the industry reduce its carbon footprint and achieve circular economy objectives.

Another critical trend is the rise of digitalization and automation within chemical manufacturing processes. The integration of smart technologies, including artificial intelligence and the Internet of Things, allows for enhanced process optimization and real-time monitoring. These advancements lead to improved operational efficiency and quicker response times to market changes. Furthermore, data analytics play a vital role in driving innovation, enabling companies to identify new opportunities for product development and streamline supply chain management. As the chemical industry embraces these technological advancements, it positions itself for greater resilience and adaptability in a rapidly changing global market.

In 2023, the chemical industry is undergoing a significant transformation, propelled by sustainable practices that are reshaping manufacturing processes. One of the most notable innovations is the shift towards renewable feedstocks, which are replacing traditional fossil fuel-based inputs. This transition not only reduces carbon emissions but also enhances resource efficiency by utilizing bio-based materials that are abundant and less harmful to the environment. By integrating circular economy principles, companies are reimagining product life cycles, ensuring that materials are reused and recycled, thus minimizing waste and energy consumption.

Furthermore, advancements in green chemistry are paving the way for safer and more efficient production methods. Techniques such as solvent-free reactions and the use of benign solvents lower the environmental impact associated with chemical processes. Additionally, innovations in digital manufacturing technologies, like artificial intelligence and machine learning, are optimizing chemical production by enhancing precision and efficiency. These technologies enable real-time monitoring and adjustments, leading to reduced energy usage and waste generation, thus promoting a more sustainable and eco-friendly approach within the chemical sector. Through these innovations, the industry not only addresses regulatory pressures but also aligns with the growing demand for environmentally responsible practices from consumers and stakeholders alike.

The transformation of the chemical industry in 2023 is significantly driven by advancements in materials science. Advanced materials, such as nanomaterials and biopolymers, are paving the way for more sustainable and efficient chemical processes. These materials not only enhance product performance but also reduce environmental impact, aligning with global sustainability goals. The integration of smart materials into chemical manufacturing is revolutionizing traditional methods, facilitating the creation of products that are lighter, stronger, and more adaptable.

Additionally, advanced materials are enhancing the capabilities of chemical processes through innovations like self-healing polymers and energy-efficient catalysts. These innovations provide the industry with new tools to tackle pressing challenges, from waste reduction to energy consumption. By implementing these cutting-edge materials, chemical manufacturers can streamline operations and improve the lifecycle of their products, ensuring better resource management and increased economic viability. This shift towards advanced materials marks a pivotal change in how the chemical industry approaches production and sustainability, ultimately fostering a more resilient and responsible market landscape.

| Innovation | Description | Impact on Industry | Expected Adoption Year |

|---|---|---|---|

| Biodegradable Polymers | Innovative materials that decompose naturally. | Reduces plastic waste and environmental impact. | 2023 |

| Carbon Capture Materials | Materials designed to absorb CO2 emissions from the atmosphere. | Mitigates climate change effects. | 2024 |

| Smart Textiles | Textiles embedded with sensors that respond to environmental changes. | Enhances functionality in various applications. | 2023 |

| Recyclable Composites | Composites that can be fully recycled at the end of their lifecycle. | Promotes sustainability in manufacturing. | 2023 |

| Advanced Coatings | Coatings with enhanced durability and resistance properties. | Extends lifespan of products and reduces maintenance costs. | 2023 |

| Catalysts for Green Chemistry | New catalysts that enhance reactions without harmful byproducts. | Improves production efficiency while minimizing waste. | 2023 |

| Bio-based Chemicals | Chemicals derived from renewable biological resources. | Decreases reliance on fossil fuels. | 2024 |

| Energy storage materials | Materials that improve battery performance and lifespan. | Facilitates the transition to renewable energy sources. | 2024 |

| Nanotechnology Applications | Utilization of nanoscale materials for improved product performance. | Enhances strength, durability, and efficiency. | 2023 |

Digital technologies are revolutionizing the chemical industry by significantly enhancing efficiency in production processes. Automation, artificial intelligence (AI), and data analytics are becoming integral tools, allowing companies to optimize their operations. For instance, machine learning algorithms can predict equipment failures before they occur, reducing downtime and maintenance costs. Moreover, utilizing digital twin technology enables manufacturers to simulate various production scenarios, ensuring that every decision leads to improved performance and resource management.

Tips for implementing digital technologies effectively include:

As the chemical industry continues to advance, it is clear that the integration of digital technologies will not only streamline processes but also contribute to sustainability goals. By leveraging real-time data analytics, companies can monitor emissions and energy consumption closely, paving the way for greener practices. Embracing these innovations will ensure that the chemical industry remains competitive in a rapidly evolving market.

In 2023, the chemical industry is undergoing a significant transformation, heavily influenced by emerging regulations that prioritize sustainability and environmental responsibility. Governments worldwide are implementing stricter regulations aimed at reducing carbon emissions and promoting the use of sustainable materials. This shift is driving innovation as companies look to comply with these regulations while maintaining competitiveness. The emphasis on greener practices has led to the development of alternative processes that minimize waste and energy consumption, as well as an increased focus on renewable feedstock.

Additionally, regulatory frameworks are fostering collaboration between governments and chemical manufacturers, encouraging research and development of new technologies. These partnerships are paving the way for innovations such as smart manufacturing processes, digital tools for monitoring compliance, and enhanced recycling methods. Moreover, with consumer awareness rising, companies are motivated to innovate not just for regulatory compliance, but also to meet the demands of environmentally conscious customers. This evolving landscape is creating a dynamic environment where sustainability and innovation go hand in hand, reshaping the future of the chemical industry.

This chart showcases the top 10 innovations impacting the chemical industry in 2023, highlighting their significance in sustainability and regulatory compliance. The innovations range from biodegradable materials to advanced recycling processes.

Contact our team with questions, product inquiries or challenge us to engineer a solution for you.

Tel: +1 716 433 6764

Fax: +1 716 433 2850

Email: sale@ashymed.com

VanDeMark Chemical Inc.

One North Transit Road

Lockport, NY 14094 USA