In the world of chemical manufacturing, understanding the landscape of top chemical factories is essential. Renowned expert Dr. Emily Carter once stated, "The efficiency and safety of chemical factories shape modern industry." This statement highlights the importance of these facilities. They play a critical role in the global supply chain.

Across continents, various factories produce a wide range of chemicals. Each facility has its own specialties and regulatory challenges. For instance, some focus on pharmaceuticals, while others may specialize in plastics or agrochemicals. However, not all operations run smoothly. Issues such as environmental compliance and worker safety remain a concern.

As we delve deeper, we'll explore the most significant chemical factories. Their impact on economies is undeniable. Yet, we must reflect on the responsibilities they carry. The balance between production and sustainability is delicate. It calls for continuous improvement and innovation in processes.

The global chemical industry plays a vital role in modern economies. It involves the production of chemicals that are essential for various sectors. From agriculture to pharmaceuticals, chemicals are used widely. The industry generates significant revenue and employs millions worldwide.

Compressed gases, fertilizers, and polymers are just a few examples of chemical products. Factories operate under strict regulations to prevent environmental damage. However, lapses in safety measures can lead to accidents. The industry faces challenges in adopting sustainable practices. Innovation is necessary but often hindered by costs and complexity.

Emerging markets are becoming crucial hubs for chemical production. Countries in Asia and Africa are expanding their capabilities. Despite the growth, issues like pollution and worker safety persist. Addressing these concerns is essential for a healthier future. As the industry evolves, finding a balance between productivity and sustainability remains a pressing dilemma.

The chemical manufacturing sector is vast and dynamic.

It consists of various key players, each contributing uniquely to the industry. Companies range from

small enterprises to large global corporations. They manufacture an array of products, from basic

chemicals to specialized compounds.

Many companies focus on sustainable practices. However, challenges arise

in balancing production with environmental impact. Some firms find it hard to transition to eco-friendly methods.

This reluctance can hinder progress in reducing waste and emissions. Innovation often clashes with existing

processes, creating tension within the industry.

Investment in research is vital. Companies should prioritize developing

new materials and processes that meet market demands. The future requires collaboration between businesses

and researchers. However, there is always a question of whether enough is being done to address pressing issues.

The path towards improvement is ongoing, and reflection on current practices is necessary for advancement.

Modern chemical factories are evolving rapidly. Innovative technologies drive their transformation. Automation, artificial intelligence, and sustainable practices reshape the industry. Factories now operate with higher efficiency and lower environmental impact.

For successful integration, focus on training staff. Embrace new technologies but ensure your team understands them. Employee buy-in is crucial. Communication can break down barriers. Not every completion goes smoothly; sometimes, adjustments are necessary.

Advanced sensors and data analytics allow real-time monitoring. They help optimize production processes. However, the reliance on technology may lead to overconfidence. Balance is key. Regular assessments can highlight areas needing improvement. Evaluate both successes and failures to foster continuous growth.

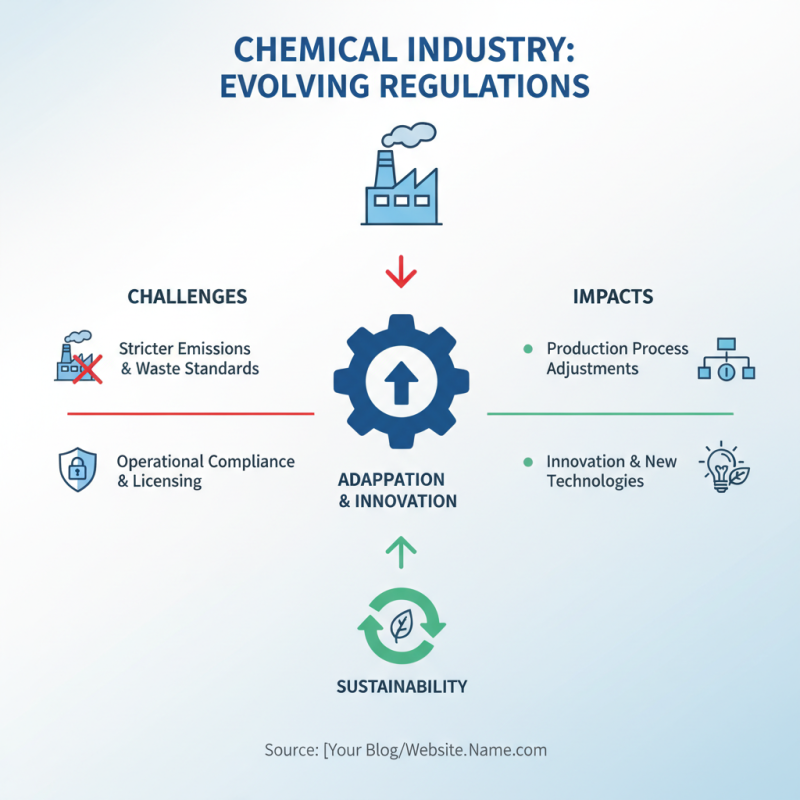

The chemical industry faces increasing scrutiny regarding environmental regulations. Many countries are establishing stricter standards for emissions and waste management. Factories must adapt to these evolving rules to maintain compliance and secure their operational licenses. This pressure encourages innovation, but it can also impede production processes.

In many cases, smaller factories struggle with these regulations. They have limited resources to invest in new technologies. This creates a disparity in the industry. Larger plants often exert more influence on policy decisions, while smaller operators face higher challenges. The result is a mixed landscape, with some companies thriving and others battling for survival.

Efforts to green chemical production continue to grow. Many facilities are exploring sustainable practices. However, not all initiatives are effective. Sometimes, desired outcomes are overshadowed by unintended consequences. Balancing profitability with environmental responsibility remains a complex task for the industry.

The global chemical manufacturing industry is on the brink of significant transformation. Environmentally friendly practices are gaining traction, as manufacturers seek sustainable alternatives. Many factories are now focusing on reducing waste and emissions. This push towards sustainability is not merely a trend; it reflects a deeper change in consumer preferences. More people want eco-conscious products.

Innovative technologies are shaping the future landscape as well. Automation and artificial intelligence are being integrated into production processes. These advancements can enhance efficiency and reduce human error. However, there are challenges. Adopting new technologies requires substantial investment. Some smaller manufacturers might struggle with these changes. The gap between large and small factories may widen, leading to market disparities.

Moreover, regulatory pressures are increasing. Governments around the world are imposing stricter environmental regulations. Factories must adapt quickly, or face penalties. This creates pressure but also opportunities for innovation. Companies that can pivot effectively may lead the market. Yet, the path to transition is complex and not without obstacles. The journey of the chemical industry is just beginning.

Contact our team with questions, product inquiries or challenge us to engineer a solution for you.

Tel: +1 716 433 6764

Fax: +1 716 433 2850

Email: sale@ashymed.com

VanDeMark Chemical Inc.

One North Transit Road

Lockport, NY 14094 USA