The increasing complexity of industrial processes has placed a premium on the effective use of specialized chemicals. Dr. Emily Chen, a noted expert in chemical engineering, emphasizes, "Specialized chemicals are pivotal for innovation in industry." This statement reflects the crucial role these substances play in enhancing product performance and sustainability.

Industries ranging from pharmaceuticals to agriculture rely heavily on specialized chemicals. Their properties can optimize production efficiency and reduce environmental impact. However, many companies struggle to fully harness their potential. Misunderstandings about the application and integration of these chemicals lead to wasted resources.

Moreover, the need for continuous improvement remains evident. Companies must learn from both successes and failures in their chemical strategies. Understanding the unique properties of specialized chemicals is essential. Such knowledge can drive innovation and reduce costs, yet many teams fall short in this aspect. Therefore, reassessment and adaptation in the use of specialized chemicals are necessary for future growth.

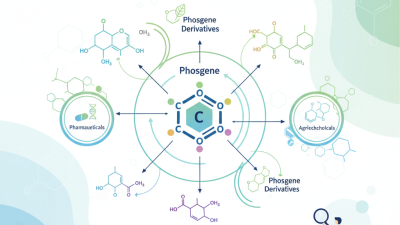

Specialized chemicals play a crucial role in various manufacturing processes. These chemicals are tailored for specific applications, boosting efficiency and product quality. From pharmaceuticals to agriculture, their diverse uses reflect the importance of understanding them thoroughly.

Industries rely on specialized chemicals for unique properties. For example, surfactants reduce surface tension in cleaning products. Catalysts speed up reactions in industrial processes. Knowing how to choose the right chemical is vital for optimal results.

Tips: Be careful with compatibility issues. Always test a small batch before full-scale use. Misjudging this can lead to waste or subpar products. Additionally, staying updated on innovations in this field is important. You might find more efficient solutions that could save costs.

The use of specialized chemicals is not without challenges. Sometimes, businesses face supply chain disruptions. Others struggle with regulatory compliance. It’s essential to reflect on these potential hurdles. Embracing collaboration with suppliers can help ensure steady access to these critical materials.

Optimizing the use of specialized chemicals in industry requires a clear focus on key areas. One critical area is formulation efficiency. Achieving the correct balance of chemicals can lead to cost savings and improved performance. However, this process often encounters challenges. Miscalculations can lead to waste or suboptimal results. Regular audits can help identify these issues, ensuring that formulations are up to date and effective.

Another vital facet is the analysis of chemical processes. Data-driven approaches can unveil insights into usage patterns. Tracking consumption rates and outcomes can highlight inefficiencies. Many facilities struggle with inadequate data collection methods. Without precise measurements, optimizing chemical use becomes difficult. Teams must prioritize establishing robust monitoring systems to support continuous improvement.

Finally, training employees on best practices is essential. Knowledge gaps can hinder the effective use of chemicals. Investing in training ensures that teams understand the implications of their actions. Mistakes can often stem from a lack of information. By fostering a culture of awareness, industries can better harness the potential of specialized chemicals.

| Key Area | Specialized Chemical | Optimization Method | Expected Outcome |

|---|---|---|---|

| Wastewater Treatment | Alum | Enhanced coagulation | Reduced sludge volume |

| Agriculture | Nitrogen fertilizers | Precision application | Increased crop yield |

| Pharmaceuticals | Catalysts | Process intensification | Higher purity |

| Food Processing | Lactic acid | Biotechnological methods | Improved food safety |

| Petrochemicals | Additives | Blending techniques | Enhanced product performance |

Managing chemical supply chains efficiently is crucial in optimizing specialized chemical use in various industries. A report from the American Chemical Society suggests that over 30% of chemical companies face significant supply chain disruptions annually. These disruptions can lead to increased costs and wasted resources. Companies need to adopt best practices to mitigate these risks effectively.

One effective strategy is improving supplier collaboration. Developing stronger relationships with suppliers enhances communication and reliability. Data from a recent industry survey indicates that firms with strong supplier partnerships reduce lead times by up to 25%. However, many companies still struggle in this area, often not prioritizing supplier engagement due to internal pressures.

Implementing advanced tracking technologies can also enhance supply chain management. Real-time monitoring systems allow companies to forecast demand accurately. Despite these benefits, a substantial number of companies have yet to adopt these technologies, relying instead on outdated methods. This gap could lead to inefficiencies and missed opportunities for optimization. Addressing these shortcomings is essential for achieving a more resilient chemical supply chain.

In today's industrial landscape, optimizing the use of specialized chemicals is vital. Innovative technologies play a pivotal role in achieving efficiency. For instance, automation systems can monitor chemical usage in real-time. These systems help identify wastage and adjust flows as necessary.

Tips: Consider integrating sensors into chemical storage areas. They provide data on levels and usage trends. This can guide timely reorders and prevent excess chemicals from sitting unused.

Another avenue is the adoption of advanced analytics. Analyzing data can uncover patterns in chemical consumption. This insight assists in adjusting processes to minimize waste. However, industries often overlook employee training on these technologies. Even the best systems fail without proper understanding.

Tips: Regularly conduct workshops for staff. Encourage feedback on technology performance. Their insights can lead to further optimizations and improvements.

Inevitably, challenges arise when implementing these new practices. A common issue is resistance to change among staff. Without buy-in, even the most advanced solutions can falter. Emphasizing the benefits of these innovations can help. Clear communication around efficiency goals makes a significant difference.

Monitoring and analyzing the outcomes of chemical optimization strategies is crucial for industries. Accurate data collection can transform operations. Using a structured approach is essential. It ensures decisions are based on solid evidence. However, not every strategy produces the desired results. Continuous evaluation is key.

Tips: Regularly schedule assessments of your chemical processes. Engage team members in discussions about what works. Implement real-time monitoring systems for immediate insights.

Sometimes, unexpected challenges arise. High costs can limit the use of certain chemicals. When exploring alternatives, the effectiveness may vary. Analyze these deviations to identify potential improvements. Documenting failures is as important as noting successes. This reflection is necessary for growth.

Tips: Use failure as a learning tool. Share insights with your team for better future outcomes. Consider guest experts for new perspectives on optimization.

Contact our team with questions, product inquiries or challenge us to engineer a solution for you.

Tel: +1 716 433 6764

Fax: +1 716 433 2850

Email: sale@ashymed.com

VanDeMark Chemical Inc.

One North Transit Road

Lockport, NY 14094 USA