In the realm of industry and laboratory work, ensuring safety with chemicals is of paramount importance. Dr. Emily Carter, a leading expert in chemical safety, emphasizes, "Understanding the properties and hazards of chemicals is the first step to prevent accidents and ensure a secure working environment." With an increasing number of industries relying on chemical substances for various applications, the potential for exposure to hazardous materials necessitates a comprehensive approach to safety.

Implementing strict safety protocols is vital in mitigating risks associated with chemical handling. By adhering to best practices and guidelines, workers can protect themselves and their colleagues from accidental spills, reactions, and health risks. The need for robust training and awareness cannot be overstated, as even minor oversights can lead to serious consequences. This article will outline the top 10 essential safety tips for handling chemicals, aiming to enhance the knowledge and preparedness of all personnel involved in this critical field.

Incorporating these safety measures will not only optimize operational efficiency but also foster a culture of safety with chemicals that safeguards the well-being of individuals and the environment. As we delve into these essential tips, we aim to equip readers with the knowledge needed to navigate the complexities of chemical handling safely and effectively.

Chemical safety is of paramount importance in a variety of environments, ranging from laboratories and industrial sites to educational institutions and even households. Understanding the properties and potential hazards of the chemicals being used is essential for mitigating risks associated with spills, exposure, or improper handling. Each environment presents unique challenges; for example, labs may involve reactive substances requiring precise handling, while industries might deal with bulk chemicals that could have severe consequences in case of accidents.

In addition, effective communication regarding safety protocols and proper training is critical across all settings. Employees and users should be well-informed about Material Safety Data Sheets (MSDS), proper storage techniques, and the use of personal protective equipment (PPE). Regular safety drills and awareness programs can aid in reinforcing these practices, ensuring that everyone involved is prepared to act responsibly when handling chemicals. By fostering a culture of safety, organizations can significantly reduce the likelihood of incidents and create a safer environment for all.

When handling chemicals, the appropriate personal protective equipment (PPE) is crucial to ensure worker safety and minimize exposure to hazardous substances. The National Institute for Occupational Safety and Health (NIOSH) emphasizes that the right PPE can significantly reduce the risk of chemical burns, respiratory issues, and other health-related incidents. According to reports from the Occupational Safety and Health Administration (OSHA), over 40% of workplace injuries in chemical handling fields are attributed to inadequate use of PPE. This highlights the importance of not only having the correct equipment but also ensuring it is regularly inspected and well-maintained.

Key components of essential PPE include safety goggles, gloves, lab coats, and respiratory protection. Safety goggles protect the eyes from splashes while ensuring that they fit snugly to prevent gaps. Chemical-resistant gloves are vital, as they safeguard against direct skin contact with dangerous substances. Additionally, respiratory protection, such as masks or respirators, is necessary when handling volatile chemicals or those that emit harmful fumes. A report by the American National Standards Institute (ANSI) notes that nearly 30% of respiratory-related incidents in chemical environments could have been avoided with proper respirators. Adopting comprehensive safety measures, including proper PPE, is essential for safeguarding workers involved in chemical handling activities.

| Tip No. | Safety Tip | Personal Protective Equipment (PPE) | Description |

|---|---|---|---|

| 1 | Read Labels and Safety Data Sheets | Safety Goggles | Always check labels for information on hazards and safe handling. |

| 2 | Use Compatible Containers | Chemical-Resistant Gloves | Ensure that containers are suitable for the chemical's properties. |

| 3 | Work in a Well-Ventilated Area | Respirator Mask | Ensure good airflow to avoid inhaling toxic fumes. |

| 4 | Never Eat or Drink in the Laboratory | Lab Coat | Prevent contamination and accidental ingestion of chemicals. |

| 5 | Maintain a Clean Working Environment | Foot Protection | Keep surfaces free of spills and clutter to avoid accidents. |

| 6 | Use Fume Hoods When Necessary | Face Shield | Utilize fume hoods to protect against hazardous fumes. |

| 7 | Know Emergency Procedures | Emergency Shower | Be familiar with the location and use of safety equipment. |

| 8 | Label All Chemicals Clearly | Chemical Spill Kit | Ensure all chemicals are correctly labeled to avoid confusion. |

| 9 | Dispose of Chemicals Properly | Waste Container | Follow local regulations for chemical disposal. |

| 10 | Wear Appropriate Clothing | Long-Sleeved Shirt and Pants | Protect skin from chemical spills with appropriate attire. |

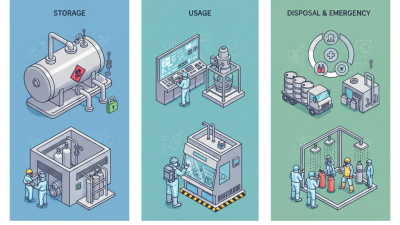

When it comes to handling hazardous chemicals, proper storage techniques are paramount for ensuring safety in your workspace. One essential tip is to always store chemicals in clearly labeled containers. This not only helps in identifying the contents but also reduces the risk of accidents caused by mistaken identity. Use chemical-resistant labels that can withstand exposure to the stored materials and environmental conditions.

Another important aspect of chemical storage is maintaining appropriate temperature and humidity levels. Certain chemicals can become volatile or unstable if exposed to extreme conditions. Therefore, it is crucial to store them in a climate-controlled area, ideally with a consistent temperature suited to the specific chemical. This prevents degradation and potential hazardous reactions from occurring.

Lastly, consider the organization of your storage area. Keep incompatible chemicals separated to avoid any dangerous reactions. For example, acids and bases should not be stored near each other, and flammable substances should be kept away from oxidizers. By implementing these tips, you can create a safer environment for working with chemicals and minimize the risks associated with their storage.

Handling chemicals safely is critical in various industries, and understanding the emergency procedures for chemical spills and exposures is vital for maintaining workplace safety. According to the National Institute for Occupational Safety and Health (NIOSH), approximately 40% of all work-related injuries in the United States are related to hazardous materials. Therefore, having clear emergency protocols can significantly mitigate risks.

In the event of a chemical spill, the first step is to evacuate the area immediately. It's essential to alert co-workers and follow the established emergency communication system. Personal Protective Equipment (PPE) should always be readily available to prevent exposure. After ensuring safety, report the spill to the designated personnel who are trained to handle such incidents. For respiratory exposures, move the affected person to fresh air and provide them with oxygen if available, while avoiding any entry into the contaminated area.

Tip: Always keep Material Safety Data Sheets (MSDS) for all chemicals accessible. These documents provide essential information on handling, hazards, and emergency response procedures for specific substances, ensuring you are well-prepared. Another critical tip is to conduct regular training sessions on how to respond effectively to chemical emergencies. This ensures that all employees are aware of the procedures and can act promptly and efficiently in case of an actual incident, thereby reducing the chances of injury and contamination.

Training and awareness programs are critical components in ensuring safe chemical handling practices across various industries. According to the National Safety Council (NSC), organizations that implement comprehensive training initiatives report a 40% decrease in workplace incidents involving hazardous materials. Proper education not only informs employees about the properties and risks associated with different chemicals but also reinforces adherence to safety protocols. These programs should encompass a thorough understanding of Material Safety Data Sheets (MSDS), proper use of personal protective equipment (PPE), and emergency response techniques.

In addition to formal training sessions, ongoing awareness campaigns can significantly bolster safety culture within an organization. Data from the American Society of Safety Professionals indicates that companies with continual safety training and refresher courses witness a 30% drop in accidents related to chemical handling. Interactive workshops, hands-on training exercises, and regular safety drills help employees retain crucial safety information and foster a proactive approach to risk management. By embedding safety into the workplace culture through these training and awareness programs, organizations can create a more informed and vigilant workforce, ultimately reducing the probability of chemical-related incidents.

Contact our team with questions, product inquiries or challenge us to engineer a solution for you.

Tel: +1 716 433 6764

Fax: +1 716 433 2850

Email: sale@ashymed.com

VanDeMark Chemical Inc.

One North Transit Road

Lockport, NY 14094 USA