In today's diverse industrial landscape, choosing the right specialized chemicals is crucial. These compounds play a pivotal role in various applications, including manufacturing, agriculture, and pharmaceuticals. Selecting the appropriate chemicals tailored to specific needs can optimize processes and enhance product quality.

However, the selection process often feels overwhelming. Many factors come into play, including compatibility, safety, and environmental impact. It’s easy to make hasty decisions that could lead to unwanted outcomes. A thorough understanding of your industry’s unique requirements is essential.

Consider the implications of your choices. For instance, opting for low-cost alternatives may initially seem appealing, but could lead to performance issues. Specialized chemicals require careful evaluation. Balancing cost and functionality is a challenge every industry faces. Reflect on what works best for your specific situation and strive for informed decisions.

Choosing the right specialized chemicals for your industry starts with understanding your specific requirements. Each industry has unique needs based on processes, regulations, and product standards. Identifying what you truly need is crucial.

For instance, in the pharmaceutical sector, purity and consistency are vital. Companies often use numerous tests to determine suitability. You might think all chemicals are the same, but their application can greatly vary. Some may not perform well under specific conditions, creating issues down the line.

Tips:

1. Conduct thorough research on your industry’s common practices.

2. Consult with experts who know the regulations and standards.

In manufacturing, durability and performance matter most. Chemical choices affect production efficiency and product quality. It’s essential to balance cost with the right specifications. Ask yourself if you're prioritizing price over quality. That could lead to problems later. Embrace continuous evaluation of your chemical needs as processes evolve.

Tips:

- Keep a close eye on industry trends and changes.

- Regularly assess supplier performance.

This ongoing process helps maintain optimal efficiency. Sometimes mistakes will happen, and that’s part of the learning curve. Embrace them to improve future selections. Understanding your specific chemical requirements is not just a task; it’s a continuous journey.

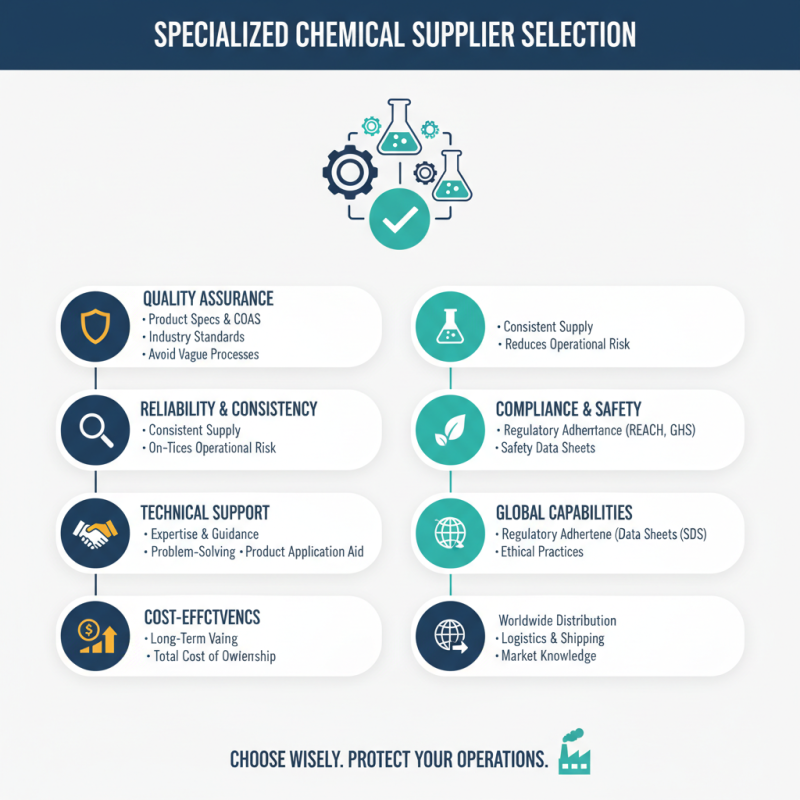

When selecting specialized chemicals for industry needs, regulatory compliance is crucial. Different sectors have unique regulations that govern the use of chemicals. Knowing these regulations can save time and money. Ignoring them can lead to serious consequences. It is essential to understand local laws and international guidelines. Compliance checks should be done regularly.

Researching chemical properties is important. Documentation must reflect the correct data. Safety data sheets (SDS) are vital. These documents provide essential information about handling, storage, and disposal. Mistakes in this area could result in hazardous situations. Thus, diligence in verifying information is necessary.

Organizations need to frequently review compliance status. Failing to keep up can create liabilities. Chemical approvals may change over time. Staying informed on these updates can be challenging. Engaging with industry experts can provide insights. This collaboration can enhance understanding and set a proactive stance toward compliance.

Selecting the right specialized chemicals for your industry requires careful assessment of their performance and efficacy. Understanding the specific needs of your application is crucial. Different industries have unique challenges. For instance, the chemical stability needed for a manufacturing process can vary dramatically from one sector to another.

Consider the intended use of the chemicals. Are they meant for production, formulation, or treatment? Each application may demand different properties. For a coating application, adhesion and durability are key. In contrast, a catalyst needs to accelerate a reaction efficiently. Testing the chemicals under real conditions can deliver valuable insights.

After evaluation, it’s important to analyze the results critically. Are the chemicals delivering the expected outcomes? Documentation of performance can reveal patterns over time. If performance falls short, reflect on the choices made. Perhaps a different chemical compound could yield better results. Rethinking your initial assessment might lead to improved processes and outcomes.

| Chemicals | Industry Application | Performance Metrics | Efficacy Rating | Environmental Impact |

|---|---|---|---|---|

| Acetic Acid | Food Processing | pH Adjustment, Solvent Properties | 8/10 | Low Toxicity |

| Sodium Hydroxide | Textile Industry | Alkali Strength, Cleaning Agent | 9/10 | Moderate Hazard |

| Ammonium Sulfate | Agriculture | Nutrient Supply | 7/10 | Low Impact |

| Formic Acid | Leather Tanning | Tanning Agent, pH Control | 8/10 | Low to Moderate |

| Sodium Bicarbonate | Baking Industry | Leavening Agent | 10/10 | Environmental Friendly |

When selecting a supplier for specialized chemicals, several key factors come into play. Quality assurance is paramount. Always ask for product specifications and certificates. Verify that the supplier adheres to industry standards. If their quality processes seem vague, consider it a red flag. Inconsistent quality can lead to operational failures and increased costs.

Communication is crucial. A good supplier should be responsive to inquiries and able to provide technical support. If they are slow to respond or dismiss your questions, think twice. Trust and transparency are vital in such partnerships.

**Tips:**

- Check reviews and feedback from other clients.

- Understand their quality control processes.

- Evaluate their flexibility in meeting your needs.

Sometimes, suppliers may push you towards certain products. Don’t feel pressured to commit. Take your time to evaluate alternatives. This choice could impact your production significantly. Balanced decisions often lead to better outcomes. Don’t overlook the importance of researching and reflecting on your options.

When budgeting for specialized chemical solutions, it's essential to consider various factors. The initial cost is just one piece of the puzzle. Equipment and processing needs can spike the overall expense. You might find that the cheapest option isn't the most efficient in the long run. This might lead to increased operational costs.

Cost analysis helps identify the long-term value of a chemical solution. Using a more expensive chemical may actually reduce waste and downtime. It's crucial to assess your specific industrial needs. Gather data on usage rates and potential savings. Sometimes, investments in quality pay off over time.

Don’t overlook hidden costs either. Shipping, storage, and disposal can add up quickly. Manufacturers often have specific protocols that can affect cost efficiency. That’s why gathering quotes from multiple suppliers is beneficial. Ensure you don’t rush this process; costs can vary widely. Reflecting on your choices can reveal gaps in your budgeting strategy.

Contact our team with questions, product inquiries or challenge us to engineer a solution for you.

Tel: +1 716 433 6764

Fax: +1 716 433 2850

Email: sale@ashymed.com

VanDeMark Chemical Inc.

One North Transit Road

Lockport, NY 14094 USA