In the rapidly evolving landscape of chemical solutions, the demand for "tailored chemicals" has surged as industries seek customized formulations to meet specific needs. As Dr. Emily Hart, a leading expert in chemical engineering, aptly noted, "The future of manufacturing lies in our ability to adapt chemical solutions to fit the unique challenges faced by businesses today." This insight underscores the importance of developing tailored chemicals that not only enhance performance but also optimize processes across various applications.

In 2023, the industry is witnessing an unprecedented shift toward personalized chemical solutions. As traditional one-size-fits-all approaches become less effective, companies are turning to bespoke formulations to tackle complex challenges. Tailored chemicals enable organizations to achieve greater efficiency, sustainability, and innovation, ultimately driving competitive advantage in their respective markets.

With advancements in technology and a growing understanding of material science, the production of tailored chemicals is becoming more accessible and refined. This evolution not only benefits manufacturers but also promotes environmental responsibility by minimizing waste and resource consumption. As the demand for customization continues to grow, the role of tailored chemicals in creating effective, sustainable solutions is more critical than ever.

In the modern industrial landscape, tailored chemicals are increasingly playing a pivotal role in creating customized solutions that meet specific customer needs. According to a recent market analysis by Grand View Research, the global market for specialty chemicals is expected to reach approximately $1.9 trillion by 2025, driven by an increasing demand for high-performance products across various sectors, including pharmaceuticals, agriculture, and electronics. The ability to engineer chemical properties allows manufacturers to adjust formulations to enhance performance, reduce costs, and minimize environmental impact.

One significant trend in the industry is the rise of green chemistry, which focuses on designing chemical products and processes that reduce or eliminate hazardous substances. The American Chemical Society reports that implementing green chemistry principles can lead to a reduction in waste generation by up to 90%, thereby offering a sustainable alternative in the production of tailored chemicals. This approach not only supports environmental goals but also aligns with consumer preferences for sustainable products.

**Tip:** When considering customized chemical solutions, it's essential to conduct a thorough needs assessment to understand the specific requirements and regulatory standards that apply to your industry. Engaging with chemical suppliers during the early stages of product development can facilitate innovative solutions tailored to your unique specifications.

**Tip:** Additionally, staying informed about advances in chemical technology can provide insights into new materials and formulations that may offer superior performance or sustainability benefits. Collaboration with research institutions can be beneficial in accessing cutting-edge developments in the field.

Customized chemical solutions have increasingly become vital across various industries, catering to specific requirements and enhancing product performance. According to a recent report by MarketsandMarkets, the global market for tailored chemicals is expected to grow from $45 billion in 2023 to $70 billion by 2028, reflecting a compound annual growth rate (CAGR) of 9%. This growth is driven by the need for high-performance materials in sectors such as pharmaceuticals, agrochemicals, and advanced manufacturing.

Key applications of customized chemical solutions can be seen in the pharmaceutical industry, where precision formulations are essential for drug efficacy and safety. In 2022, it was reported that over 50% of new drug formulations relied on specialized chemical compounds to enhance bioavailability and target delivery, significantly reducing side effects and improving patient outcomes. Similarly, the agrochemical sector increasingly employs tailored chemical formulations to develop pest-resistant crops and optimize fertilizer use, leading to higher yields and reduced environmental impacts. A study from the Food and Agriculture Organization (FAO) highlighted that customized agrochemicals could improve crop productivity by as much as 30%, showcasing their growing importance in sustainable agriculture practices.

Furthermore, in advanced manufacturing, industries are adopting bespoke chemical solutions to improve materials' properties like durability and thermal resistance. For instance, composite materials enhanced with specialized chemical additives offer better performance in aerospace and automotive applications, with the global demand projected to reach $20 billion by 2025. This trend underscores the significant role of tailored chemicals in fostering innovation and efficiency across various applications, making them indispensable for modern technological advancements.

The tailored chemicals market is experiencing transformative trends in 2023, driven by the increasing demand for customized solutions across various industries such as pharmaceuticals, agriculture, and consumer products. According to a recent report by Market Research Future, the tailored chemicals sector is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2030. This growth is largely attributed to advancements in technology, allowing for more precise formulation processes that cater to specific customer needs.

Additionally, sustainability has emerged as a pivotal trend influencing the tailored chemical market this year. Environmental concerns are prompting companies to invest in greener, bio-based chemicals that minimize ecological footprints. A study by Deloitte highlights that nearly 60% of chemical companies are now prioritizing sustainability in their R&D agendas, aiming to innovate their product lines with environmentally friendly alternatives. This shift not only responds to regulatory pressures but also aligns with consumer preferences for sustainable products, thereby shaping the future landscape of the tailored chemical market.

As customer demands evolve, the importance of collaboration between chemical manufacturers and end-users is becoming increasingly vital. Innovations driven by real-time data analytics and customer feedback are enabling companies to develop highly specific solutions that meet the unique challenges faced by different sectors. In this dynamic environment, staying attuned to market trends and consumer insights will be essential for companies looking to thrive in the tailored chemicals arena.

| Chemical Type | Application Area | Market Trend | Growth Rate (CAGR %) | Region |

|---|---|---|---|---|

| Specialty Polymers | Automotive | Sustainability | 6.5% | North America |

| Adhesives | Construction | Functionalization | 4.2% | Europe |

| Surfactants | Personal Care | Natural Ingredients | 5.0% | Asia-Pacific |

| Coatings | Industrial | Eco-friendly Solutions | 7.1% | Latin America |

| Inks | Packaging | Digital Printing | 3.8% | Middle East |

The development of customized chemicals is influenced by a variety of factors that cater to the unique needs of different industries. Firstly, the specific requirements of end-users play a pivotal role in driving innovation. These requirements may include performance characteristics such as solubility, stability, and reactivity, and often vary significantly across sectors like agriculture, pharmaceuticals, and manufacturing. The ability to tailor chemicals to meet these specifications not only enhances product effectiveness but also promotes sustainability by reducing waste and improving resource efficiency.

Another crucial factor is the advancing technology in chemical synthesis and processing. Recent advancements have enabled more precise control over chemical structures and properties. Techniques such as computer-aided design and high-throughput screening have streamlined the development process, allowing chemists to experiment with various formulations quickly and efficiently. Additionally, increased collaboration between academia and industry fosters an environment conducive to research and innovation, leading to the emergence of novel customized solutions that address the evolving challenges faced by various industries.

Lastly, regulatory considerations are increasingly impacting the development of tailored chemicals. Compliance with environmental regulations and safety standards is essential, and custom chemicals must often undergo rigorous testing and approval processes. As businesses strive to meet these standards while delivering value to their customers, they are incentivized to invest in sustainable practices, making the development of customized chemicals a dynamic and rapidly changing field.

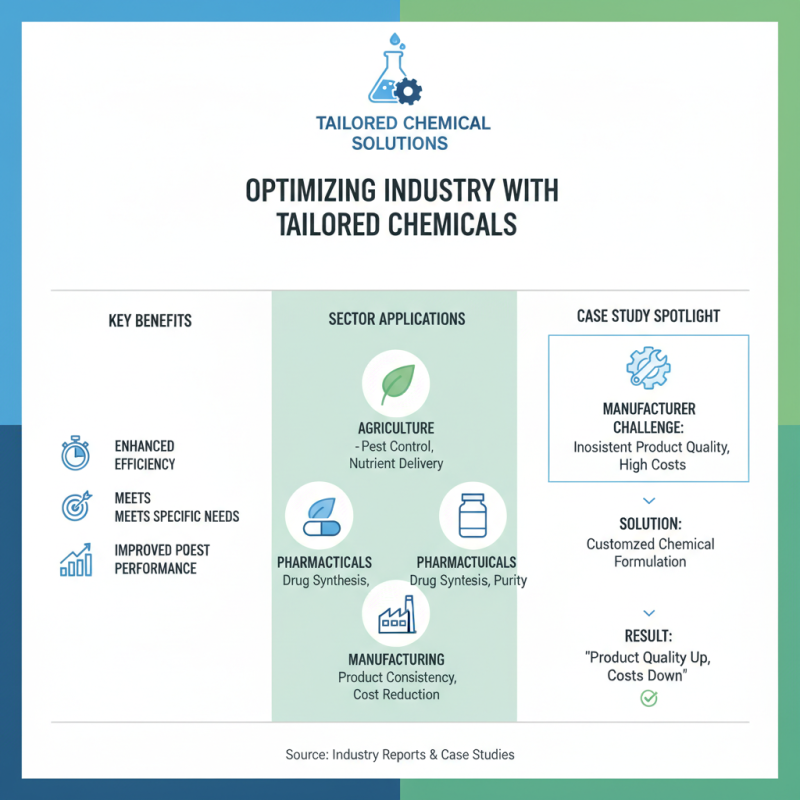

Tailored chemical solutions have become a critical component for industries aiming to enhance their operational efficiency and meet specific performance requirements. In recent years, several case studies have demonstrated the effectiveness of customized chemical formulations across various sectors, including agriculture, pharmaceuticals, and industrial manufacturing. For instance, one notable case involved a manufacturer who faced challenges with product consistency and performance. By collaborating with chemical engineers to develop a tailored solution, they improved product quality while significantly reducing production costs.

Tips: When exploring tailored chemical solutions, it’s essential to conduct thorough research on the specific needs of your application. Engage with experts in the field who can provide insights and guidance based on previous case studies relevant to your industry. This proactive approach can lead to more innovative solutions that cater to your unique operational challenges.

Another successful case highlights a leading agricultural firm struggling with pest control in certain crops. By customizing their chemical treatment, the firm achieved higher efficacy and reduced environmental impact, leading to better crop yields. Such solutions not only address immediate issues but also promote sustainable practices, showcasing the dual benefits of tailored chemicals in modern applications.

Tips: Keep communication channels open with your chemical suppliers to ensure continuous improvement and optimization of tailored solutions. Regular feedback can help refine formulations and keep pace with evolving market demands.

Contact our team with questions, product inquiries or challenge us to engineer a solution for you.

Tel: +1 716 433 6764

Fax: +1 716 433 2850

Email: sale@ashymed.com

VanDeMark Chemical Inc.

One North Transit Road

Lockport, NY 14094 USA