The chemical complex industry stands at the forefront of innovation, playing a pivotal role in numerous sectors such as pharmaceuticals, agriculture, and renewable energy. According to recent reports from the Global Chemical Industry Outlook, the market is projected to grow significantly, with estimates suggesting a compound annual growth rate (CAGR) of approximately 5% over the next five years. This growth is driven by a heightened demand for sustainable and efficient solutions that address global challenges, including climate change and resource scarcity.

Innovations within chemical complexes are revolutionizing the way materials are produced and utilized. Advances in process optimization, such as the integration of artificial intelligence and machine learning, have enabled companies to enhance their operational efficiency and reduce costs. Furthermore, breakthroughs in green chemistry and bioprocessing are paving the way for environmentally friendly production methods, reducing waste and improving product lifecycle impacts. As the industry pivots towards sustainability, these innovations not only meet regulatory requirements but also align with the growing consumer emphasis on eco-conscious products.

In this dynamic landscape, identifying the top 10 chemical complex innovations is crucial for industry stakeholders aiming to remain competitive. These innovations are instrumental in shaping the future of the chemical complex, ensuring a balance between economic viability and environmental responsibility. As such, a comprehensive understanding of these transformative changes is essential for any professional navigating the complexities of the industry today.

The landscape of the chemical industry is undergoing a significant transformation as innovations continue to emerge, driven by technological advancements and sustainability demands. Today, chemical complexes are increasingly integrating automation, machine learning, and data analytics to enhance efficiency and reduce operational costs. These innovations enable real-time monitoring of processes, predictive maintenance, and optimization of resources, resulting in improved productivity and reduced environmental footprints.

Moreover, advancements in green chemistry and bioprocessing are reshaping the way chemicals are produced. By utilizing renewable resources and engineering biological systems, companies are developing more sustainable production methods that minimize waste and utilize less energy. This shift not only meets regulatory pressures but also caters to consumer demand for environmentally friendly products. As a result, the chemical industry is poised to play a pivotal role in addressing climate challenges while continuing to deliver essential materials for various applications.

This bar chart illustrates the impact of various chemical complex innovations on industry efficiency, sustainability, and safety. The data reflects the relative advancements made in the following areas:

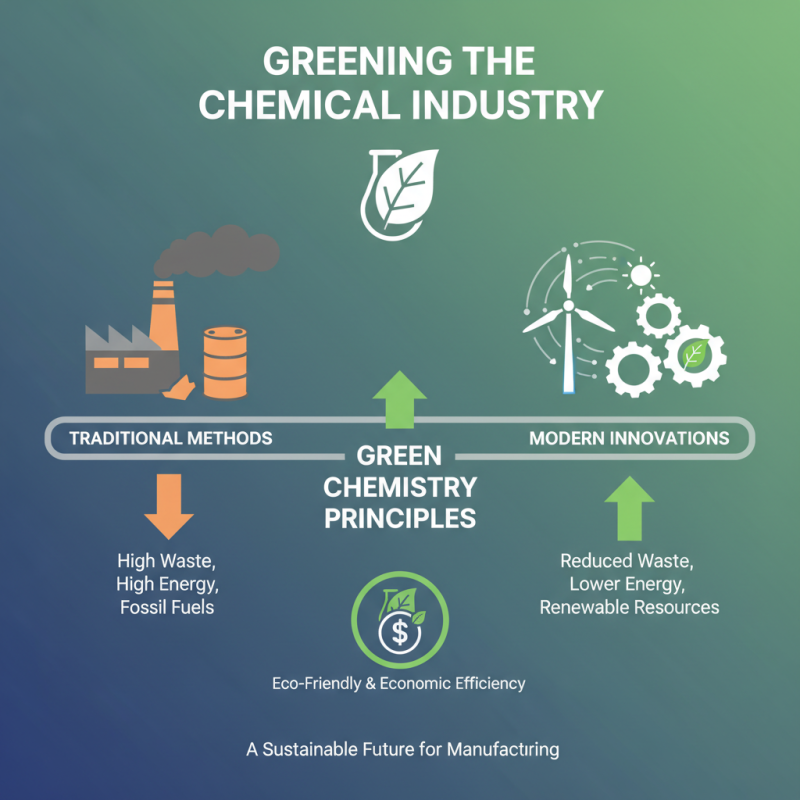

The chemical industry has long been associated with significant environmental challenges, but recent innovations are reshaping its landscape with sustainability at the forefront. Advanced technologies in chemical processes are now enabling manufacturers to produce materials with less waste and lower energy consumption. For instance, the development of green chemistry principles has led to methods that utilize renewable resources, significantly reducing reliance on fossil fuels. Such practices not only promote eco-friendliness but also enhance economic efficiency, creating a promising pathway for the industry.

Moreover, the implementation of closed-loop systems is gaining traction, where waste materials from one process are repurposed as raw materials for another. This not only minimizes waste but also conserves valuable resources, exemplifying a circular economy approach within the sector. Innovations such as biochemicals and renewable feedstocks are providing alternatives to traditional petrochemical processes, further decreasing the carbon footprint. As companies continue to embrace these sustainable practices, the chemical industry is poised for a transformation that prioritizes environmental stewardship while meeting the needs of a growing global population.

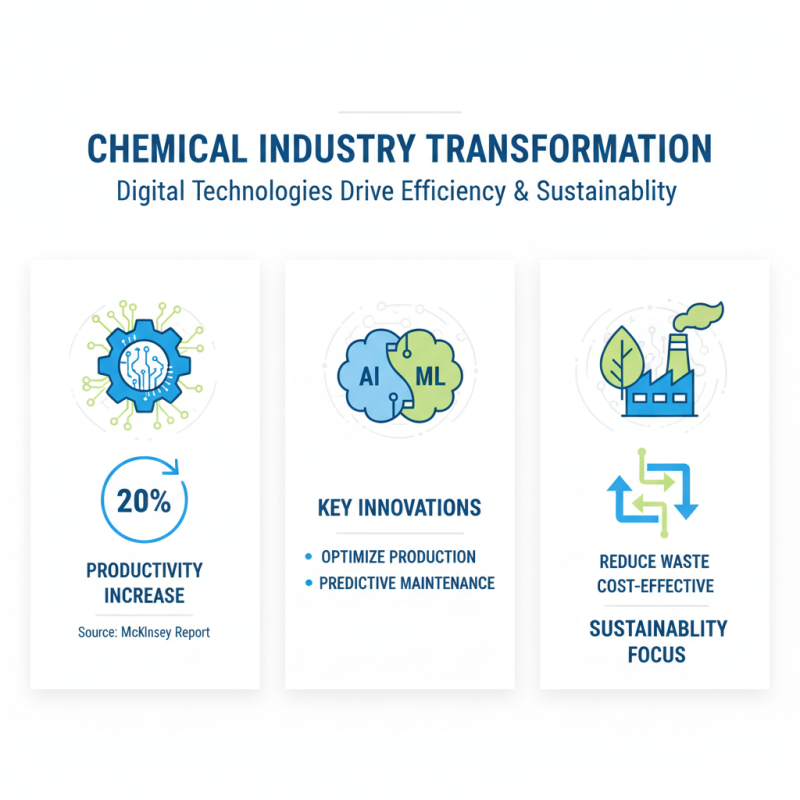

The chemical industry is undergoing a significant transformation as cutting-edge technologies enhance efficiency in chemical processes. According to a recent report by McKinsey & Company, the adoption of digital technologies in the chemical sector could lead to a productivity increase of up to 20%. Innovations such as artificial intelligence (AI) and machine learning (ML) are reshaping traditional workflows, enabling companies to optimize production schedules and reduce downtime through predictive maintenance. This transition is not only cost-effective but also minimizes waste, aligning with the industry's growing focus on sustainability.

Moreover, advancements in automation are proving crucial in enhancing operational efficiency. The World Economic Forum highlights that implementing automated systems can reduce operational costs by as much as 30% while improving safety measures within chemical plants. Process innovations, such as continuous manufacturing and advanced analytics, allow real-time monitoring of chemical processes, resulting in higher yield and reduced energy consumption. According to a study by the International Energy Agency (IEA), integrating these technologies could cut energy use in chemical production by up to 15%, significantly contributing to global sustainability efforts and climate goals. The synergy between innovative technologies and energy efficiency is setting a new standard for the future of the chemical industry.

The integration of automation and AI into chemical complex operations is revolutionizing the industry by enhancing efficiency and safety. These technologies enable real-time data analysis, allowing companies to optimize their processes and reduce downtime. Automation can streamline repetitive tasks, minimizing human error and increasing production consistency. With the ability to monitor equipment and processes remotely, operations can respond swiftly to any disturbances, leading to improved reliability and minimized operational risks.

Tips: Embracing a phased implementation of automation can ensure a smoother transition. Companies should start with pilot projects to evaluate the system’s impact before full-scale deployment. Investing in employee training on these new technologies is crucial; a skilled workforce can leverage automation tools to enhance productivity and innovation.

Another significant aspect is the use of AI-driven predictive maintenance strategies, which can transform how maintenance is conducted in chemical complexes. By analyzing historical data, AI algorithms can predict equipment failures before they occur, enabling proactive maintenance that saves costs and enhances safety. This predictive capability allows for better resource allocation and ensures that production schedules are not disrupted.

Tips: Regularly updating AI models with new data can improve accuracy and effectiveness. Additionally, fostering collaboration between IT and operational teams can yield better insights and optimized solutions, ultimately leading to a more resilient operational framework.

The landscape of chemical complex innovations is rapidly evolving, with numerous trends on the horizon shaping the industry’s future. One of the most significant trends is the emphasis on sustainability and eco-friendly practices. As regulatory environments tighten and public awareness of environmental issues increases, chemical complexes are investing heavily in green chemistry and bioprocessing technologies. This shift not only reduces the ecological footprint of chemical production but also aligns with consumer demands for sustainable products, paving the way for a circular economy.

Another emerging trend is the integration of digital technologies and artificial intelligence into chemical manufacturing processes. Companies are leveraging big data analytics and machine learning to optimize production efficiency, reduce waste, and enhance safety protocols. Predictive maintenance powered by AI ensures equipment operates at peak efficiency, mitigating costly downtimes and fostering innovative process improvements. As these technologies continue to develop, they promise to revolutionize operational capabilities, making chemical production more agile and responsive to market changes.

Furthermore, advancements in collaborative robotics, or cobots, are becoming increasingly prevalent. These robots are designed to work alongside human operators, increasing productivity while ensuring safety in hazardous environments. The synergy created by combining human ingenuity with robotic precision will significantly enhance process control and operational effectiveness across chemical complexes. As these innovations unfold, the industry is poised for a dynamic transformation that will redefine manufacturing standards and pave the way for new opportunities in the coming years.

| Innovation | Description | Impact on Industry | Future Trends | Sustainability Aspect |

|---|---|---|---|---|

| Advanced Catalysis | Improvement in chemical reaction speed and efficiency. | Higher production rates and lower energy consumption. | Integration with AI for process optimization. | Reduced greenhouse gas emissions. |

| Bioplastics Production | Use of renewable resources for plastic manufacturing. | Reduced dependency on fossil fuels. | Expansion in consumer goods and packaging. | Decreased environmental pollution. |

| Carbon Capture Technology | Techniques to capture CO2 emissions from industrial processes. | Mitigates climate change impacts. | Integration into existing manufacturing processes. | Enhances overall sustainability measures. |

| Smart Manufacturing | Utilizing IoT and automation for production efficiency. | Increased operational efficiency and reduced waste. | Further advancement in AI and robotics. | Optimization of resource usage. |

| Green Chemistry | Design of chemical processes that reduce hazardous substances. | Safer production methods and products. | Growing emphasis on non-toxic chemicals. | Promotes environmental conservation. |

| Electrochemical Processes | Using electricity to drive chemical reactions. | Potentially lower energy costs. | Increased efficiency in material conversion. | Reduction of waste generation. |

| Waste-to-Energy Technologies | Conversion of waste materials into usable energy. | Minimizes landfill use while generating energy. | Increased adoption in urban areas. | Supports circular economy principles. |

| Digital Twin Technology | Creating a virtual representation of physical processes. | Enhanced monitoring and optimization. | More detailed predictive maintenance. | Greater efficiencies in energy usage. |

| Sustainable Water Management | Innovative techniques for water recycling and treatment. | Reduced water use and lower operational costs. | Technological advancements in filtration systems. | Environmental conservation through responsible use. |

Contact our team with questions, product inquiries or challenge us to engineer a solution for you.

Tel: +1 716 433 6764

Fax: +1 716 433 2850

Email: sale@ashymed.com

VanDeMark Chemical Inc.

One North Transit Road

Lockport, NY 14094 USA