In today's rapidly evolving industrial landscape, ensuring effective chemical compliance has become paramount for businesses. Dr. Emily Carter, a recognized expert in chemical safety, once stated, "Compliance is not just a regulatory requirement; it's a commitment to safety and sustainability." This insight sheds light on the critical need for companies to adhere to regulations regarding hazardous substances.

Chemical compliance encompasses a range of responsibilities. It involves understanding local and global regulations, proper labeling of substances, and comprehensive risk assessments. Many organizations struggle to navigate these requirements. They often overlook critical details, which can lead to costly penalties and safety mishaps. Small oversights can have significant consequences.

Implementing a robust compliance strategy requires ongoing education and employee engagement. Training programs can help workers understand the importance of handling chemicals safely. However, many companies neglect this aspect, creating an environment where compliance is not prioritized. Reflecting on these shortcomings can pave the way for a more effective compliance culture.

Chemical compliance is crucial for businesses handling hazardous materials. Regulations vary by country but typically aim to protect human health and the environment. For instance, the U.S. Environmental Protection Agency (EPA) reports that compliance violations can lead to fines exceeding $37,500 per day. It's essential to stay informed about regulations like the Hazard Communication Standard (HCS) or the Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) in the EU.

**Tip:** Regular training sessions can enhance awareness of compliance responsibilities. Training should cover hazardous materials' safe handling and reporting practices. According to a study by the National Safety Council, companies with ongoing compliance training see a 50% reduction in accidents linked to chemical exposure.

To ensure compliance, conduct regular audits. These audits reveal gaps in adherence to regulations. Companies often neglect the importance of proper labeling and Material Safety Data Sheets (MSDS). Inadequate labeling can lead to employee injuries and costly legal battles. Tracking compliance metrics is vital for maintaining standards and revealing areas needing improvement.

**Tip:** Set up a compliance calendar. Regularly update it to reflect changes in legislation or internal practices. This proactive approach can keep your business on the right side of the law and enhance workplace safety.

| Regulation/Standard | Description | Compliance Requirements | Reporting Frequency | Responsible Department |

|---|---|---|---|---|

| REACH | Registration, Evaluation, Authorisation and Restriction of Chemicals. | Pre-registration and registration of substances | Annually | Chemicals Compliance Team |

| OSHA HazCom | Occupational Safety and Health Administration Hazard Communication. | Labeling, safety data sheets, employee training | Biannually | Health & Safety Department |

| EPA TSCA | Toxic Substances Control Act. | Reporting new chemicals, inventory updates | Every 5 years | Regulatory Affairs |

| ISO 14001 | International standard for environmental management. | Establishing an environmental management system | Annual audits | Environmental Management Team |

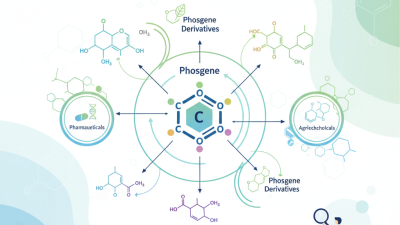

Identifying and assessing chemicals in business operations is critical for effective compliance. A recent report from the Occupational Safety and Health Administration (OSHA) states that approximately 5 million workers are exposed to hazardous chemicals each year. This statistic highlights the importance of understanding which chemicals are present in the workplace. Companies need to document all chemicals used in each operation, from manufacturing to maintenance. Failing to do so can lead to significant health risks and regulatory penalties.

Assessment begins with a thorough inventory of chemicals. Businesses should categorize these substances based on toxicity, handling methods, and potential exposure risks. Without proper categorization, companies may miss harmful chemicals in their operations. For example, the American Chemical Society recommends using Safety Data Sheets (SDS) for all chemicals. These sheets provide vital information on handling, storage, and emergency measures. Yet, many organizations overlook this resource, leading to dangerous situations.

Training employees on chemical safety is equally important. The National Institute for Occupational Safety and Health (NIOSH) highlights that frequent training reduces accidents. However, some businesses provide inconsistent or outdated training, which can leave employees vulnerable. Regular updates and assessments can help mitigate this risk. A culture of safety, combined with rigorous assessment, is necessary for a compliant and secure workplace.

Effective compliance management in chemical handling is crucial for businesses today. Creating a robust compliance management system is the backbone of this effort. Start by assessing your current practices. Identify gaps and areas for improvement. Regular audits can reveal issues you might overlook. Without these checks, compliance remains a theoretical concept rather than a practical reality.

Training your staff is key. Ensure everyone understands chemical safety protocols. Offer hands-on training sessions. These can highlight the importance of compliance. Consider role-playing scenarios to reinforce learning. But remember, even the best training can falter if not revisited periodically. Update your training protocols as regulations change. Consistency in messaging is vital.

Documentation is another critical aspect. Keep clear records of training sessions, chemical usage, and safety checks. This not only aids compliance but also helps during inspections. However, don’t just file away paperwork. Regularly review and analyze these documents. They can inform future improvements. Mistakes can teach valuable lessons, but only if you reflect on them.

Training employees on chemical safety is essential for compliance. Regular training sessions will keep safety at the forefront of everyone’s mind. It's important to use practical examples relevant to your workplace. Role-playing can help employees understand potential hazards. This method engages them better and promotes retention.

Visual aids can enhance understanding. Infographics or safety data sheets can clarify complex information. Charts illustrating proper handling techniques serve as quick references. However, not all training sessions hit the mark. Sometimes, employees might feel overwhelmed by information. Feedback is crucial to identify gaps in knowledge.

Creating a culture of safety is vital. Encourage open discussions about chemical safety practices. Employees should feel comfortable sharing concerns. A suggestion box may help shy individuals voice their thoughts. Remember, training needs to evolve with regulations and employee needs. Evaluate programs regularly for effectiveness. Adjusting strategies based on feedback ensures everyone stays informed and safe.

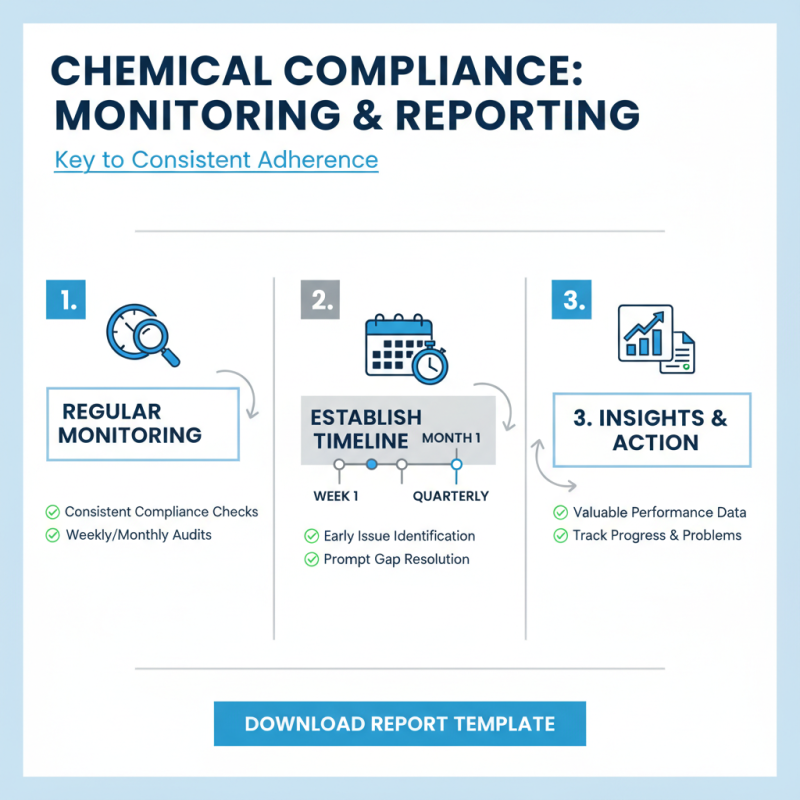

Regular monitoring and reporting are essential for effective chemical compliance. Establishing a timeline helps ensure that compliance checks happen consistently. Weekly or monthly audits can identify issues early. Regular reports provide valuable insights into compliance performance. These documents help track progress and spot recurring problems. They serve as a reminder to address compliance gaps promptly.

Using simple metrics can clarify compliance performance. Metrics like incident reports, training completion rates, and chemical inventory updates are useful. Set benchmarks to measure success. However, teams often overlook these metrics. This neglect can lead to misunderstandings or inadequate compliance. Encourage open discussions about challenges faced during compliance checks. Sharing experiences leads to collective learning.

Reflecting on compliance monitoring processes is vital. Are current methods effective? Are teams equipped with the right tools? Identifying flaws in the system is crucial for improvement. Regular feedback is essential. Sometimes, complacency can creep in. Acknowledging areas needing development is not a failure; it is a step towards growth. Continuous enhancement of processes can lead to better compliance outcomes.

Contact our team with questions, product inquiries or challenge us to engineer a solution for you.

Tel: +1 716 433 6764

Fax: +1 716 433 2850

Email: sale@ashymed.com

VanDeMark Chemical Inc.

One North Transit Road

Lockport, NY 14094 USA